Why the Offshore Drilling Process Is so Complex and Costly

The offshore drilling process requires complex machinery and large crews. At every stage, things that can go wrong, so each stage requires special care.

Feb. 1 2016, Published 2:45 p.m. ET

The offshore drilling process

In the preceding part of this series, we took a look at the broader process of oil production. In this part, let’s dive into the nitty-gritty details of the offshore drilling process. The offshore drilling industry requires complex machinery and hundreds of people. At every stage, there are things that can go wrong, so extra care needs to be taken at every stage.

Drill a hole, then drill into casing

How are offshore drilling companies getting the oil from the ocean floor? First, a large diameter hollow tube called a conductor is embedded in the seafloor along with a jet drill. When the conductor penetrates about 250 feet beneath the seabed, the jet drill is removed and a different drill bit is introduced. This drill bit is connected to a drill pipe and has special teeth that crush or break the rocks in the seafloor, making a deeper hole. Once the desired depth is reached, the drill bit and drill pipe are brought back to the surface.

A word on cement casing

Once the drill bit is brought back to the surface cement is pumped down the drill pipe and through a nozzle pushed out on the sides. The cement goes between the pipe and the conductor. After a few hours, the cement hardens. Once the cement is set, drilling continues with a smaller diameter drill bit. Drilling goes deep down into fresh rocks.

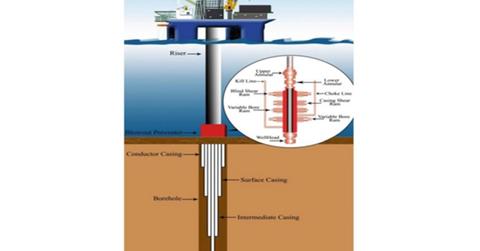

The blowout preventer and marine riser

After a suitable depth has been drilled, the drill bit is removed and replaced with a steel tube called the casing. The casing is fitted at the wellhead with what’s referred to as a BOP (blow-out preventer) placed on top of the wellhead. The main function of the BOP is to prevent the uncontrolled flow of liquid and gases during the drilling process.

But how does the oil get from the hole in the seafloor to the rig? The BOP is fitted with a riser that allows the drilled fluids to return to the surface, connecting the new oil well to the rig itself. A drill pipe is lowered down from the riser, through the BOP and into the wellhead, extending down into the well itself. Drill fluid or mud is pumped back through the pipe. The mud eventually circulates around up through the marine riser and back to the surface of the oil rig.

Drill resting and checking for oil

As drilling continues, sets of different diameters of casing are used to penetrate into the rock. Each run of casing is cemented to provide integrity. High-tech measurement devices are sent down the hole to detect features of the rock. Using a combination of sound wave tools, electrical tools, and radiation measurements, instrument readings are taken from inside the well to determine the presence of oil. With this information, it is decided whether the well should be completed for production.

Costs associated with drilling

Offshore drilling (OIH) companies like Diamond Offshore Drilling (DO), Noble Corporation (NE), Pacific Drilling (PACD), Seadrill (SDRL), Transocean (RIG), and Atwood Oceanics (ATW) receive day rates for leasing out their rigs to oil companies. Notably, this day rate, which is a rental fee that includes the rig use and crew costs, does not include the equipment rent, chemical costs, and casing costs.

Now let’s look at the largest marine oil spill in history and how it has changed the industry.