LIS Technologies Looks to Lead the Nuclear Renaissance to Shape Clean Energy by 2050

LIS Technologies plans to help usher in the nuclear renaissance amid the call for clean, sustainable energy.

Jan. 4 2025, Published 12:07 p.m. ET

The call for clean, sustainable energy is growing by the day. Experts predict that the U.S. will need up to three times its nuclear energy capacity by 2050, yet meeting even its present nuclear needs has been a challenge. To help usher in the nuclear Renaissance, investors are turning to LIS Technologies.

Nuclear energy hinges on the availability of enriched uranium. Producing this uranium in a manner that’s efficient and doesn’t leave a significant carbon footprint is one of the biggest challenges the country and the world at large face.

For decades, the main options for creating enriched uranium have been gas centrifuge and gaseous diffusion processes. Since the 1970s, however, the country’s leaders have been interested in pursuing laser enrichment technologies instead.

“Laser can be more selective, more efficient, and more elegant,” says Christo Liebenberg, co-founder and CEO of LIS Technologies, the only U.S.-based developer of advanced laser enrichment technology. “It’s more precise, it’s much cheaper, and it has a much smaller footprint. There are so many benefits to laser enrichment.”

Until now, the two types of laser enrichment have been atomic vapor laser isotope separation (AVLIS) and molecular laser isotope separation (MLIS). Although these two processes are capable of creating enriched uranium in a laboratory, some experts believe scaling challenges have prevented adoption on a commercial scale.

Some experts believe that AVLIS couldn’t produce uranium vapor pressures high enough to be economically feasible, and it had serious product collection issues. Meanwhile, MLIS relies on 16um laser systems that are prohibitively expensive and almost impossible to scale up.

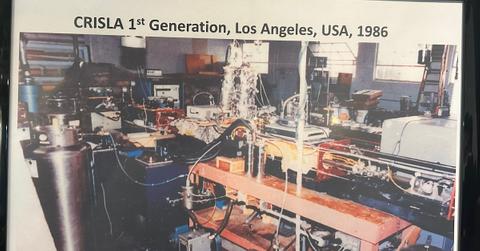

To address these issues, LIS Technologies presents its proprietary CRISLA process.

LIS Technologies believes that its CRISLA, or condensation repression isotope selective laser activation, is a laser enrichment process that uses lasers at a wavelength that is significantly less complex and much more efficient than those used for AVLIS and MLIS. This drives down costs, making it a more affordable option that opens up the path to greater small modular reactor (SMR) usage.

To address the growing demand for nuclear energy, one of the most promising options is to rely on SMRs and microreactors. As the nuclear sector currently stands, however, there just isn’t enough nuclear fuel (aka enriched uranium) to go around.

“The U.S. is looking to build up a domestic fuel manufacturing supply chain, so right now, none of these SMR companies or microreactors know where they're going to get their future fuel from,” says Liebenberg. By offering a fast and cost-effective way to produce HALEU, LIS Technologies is planning to fill that supply gap.

LIS Technologies believes that CRISLA has one other major benefit that makes it so reliable: an innovative architecture with fewer laser systems and fewer active optical components. The simplified process makes the creation of high-assay low-enrichment uranium (HALEU) much quicker to boot.

Using gas centrifuges, the uranium would have to go through many stages to be transformed from natural uranium to low-enrichment uranium (LEU) and then to HALEU. With CRISLA, however, there are only two stages or steps required to produce HALEU.

“This means a single-step enrichment process from natural to LEU,” Liebenberg says. “If you use a second enrichment step, you go from LEU all the way to HALEU.”

Other metrics that can influence the efficiency of a laser enrichment process are the mean time between failures (MTBF) and the mean time to repair (MTTR). The high reliability and low complexity of the CRISLA laser system, in turn, keep the MTBFs high and the MTTR low.

Clean energy needs to be efficient and affordable, but it must also be what’s advertised on the box: clean. Although nuclear power already has a smaller carbon footprint than fossil fuels, including natural gas, there are still concerns about waste byproducts that could pose environmental risks.

CRISLA technology addresses this issue through its efficient laser system. With CRISLA, uranium-235 can be stripped from the feed material more effectively than it could be with other lasers and enrichment methods. This means that the waste byproducts will have significantly less impact on the environment because there won’t be much leftover uranium-235 isotopes, at most 0.15% in the tails.

At the same time, the ability to produce high-assay low-enriched uranium could help extend the lifespan of advanced nuclear reactors while reducing the frequency of fuel replacement. “We believe that we have the Holy Grail of enrichment technologies,” says Jay Yu, Chairman and President of LIS Technologies.

Although the company still faces several key challenges, including concerns about the classification of the technology, LIS Technologies offers a bright path to a future fueled by cleaner, more sustainable energy. By investing in such innovation, it may be possible for the U.S. to reach its clean energy goals faster than many might have expected.