Why the quality spread on iron ore products is widening

Chinese environmental protection and pollution control measures will necessitate the use of higher content.

July 17 2014, Updated 1:00 p.m. ET

The quality spread of iron ore products is widening

The mined iron ore is usually sold to steel makers as concentrate, fines, pellets, and lump. Concentrate ore is processed into separate deleterious elements and produces a higher quality product of 63%–69% content. Lump iron is between six–30 millimeters in size, while anything below six millimeters is considered fines which have iron content ranging from 56%–66%. Pellets are produced by agglomeration and thermal treatment, with grades ranging from 67%–72% iron. The lump is richer in iron content. It’s preferred to fines because fines have to be processed through sintering first, which is a major source of pollution and sulfur dioxide. Lumps can be directly fed into a furnace for steel-making.

Why size matters?

Chinese environmental protection and pollution control measures will necessitate the use of higher content. As a result of excess supply, steelmakers are asking for discounts on lower-grade materials and suppliers have no option but to oblige. That’s why the premium spread has widened. Six months ago, the premium spread between lumps and fines with 62% content was $8–$10 per ton. Currently, it’s about $17–$18 per ton.

Rio Tinto (RIO), BHP Billiton (BHP), Vale (VALE), won’t be impacted much by development. However, players like Cliffs Natural Resources (CLF) and Fortescue metals will be impacted negatively because the bulk of their production is low grade. These companies form 18% of the iShares S&P Global Materials Sector Index Fund (MXI).

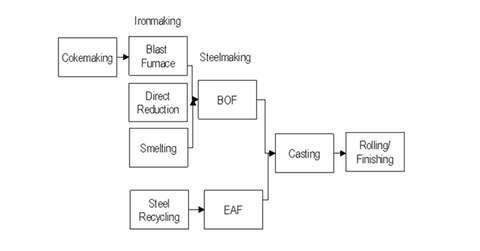

Iron ore processing to steel making

The premium or discount for any iron ore product is determined by how easy or difficult, time consuming, expensive, and less or more polluting the product is to final production of steel. The ore goes through concentration, which includes processes to upgrade the iron content by removing impurities. Next, it goes through beneficiation, which makes ore more usable by improving its physical properties. Then, the ore is mixed with coke and heated to form an iron rich clinker called sinter. Coke, ore, and sinter are then put into a blast furnace, together with limestone. A hot air blast is done, which separates the iron in molten form at the bottom of the furnace, which forms pig iron. This iron is processed further by removing carbon and adding steel scrap and other metals according to the nature and purpose for which the final product will be used, which forms steel. It takes about 1.5 tons of iron ore to produce one ton of steel.